Among the many online services for PCB manufacturing, I was impressed by the SeeedStudio‘s offering: they aggregate many orders to offer professional service at a very competitive price.

I tried out the service ordering 10 PCBs, maximum size 5x5cm, with a price of 9.90$ + 3.52$ for shipping (to Italy) – less then 10 euro. SeeedStudio doesn’t accept Eagle .brd files, so I thought to write this short guide with some hints to use Fusion PCB at its best.

Download from Fusion PCB webpage, two archives:

- DRU for 2-layer board

- Seeed Gerber Generater 2-layer board

Unzip the first one in dru subfolder of the main Eagle installation folder, the second in cam subfolder.

Open your Eagle project and focus on Board layout: to test PCB compliance to Fusion PCB rules, click on Drc button in the right toolbar, then click on Load… and choose the file Fusion_eagle_rule_v1.1.dru:

Click on Check, if everything is ok, DRC Errors window won’t show any errors; otherwise you have to modify your PCB following the error messages.

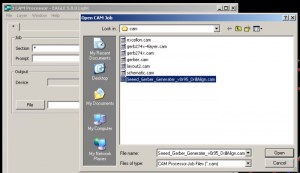

To export the project, from File menu click on CAM Processor.

In CAM Processor window, click on File -> Open -> Job… and choose the Seeed_Gerber_Generater_v0r95_DrillAlign.cam file:

Click on Process Job: Eagle will write some new files in our project’s folder.

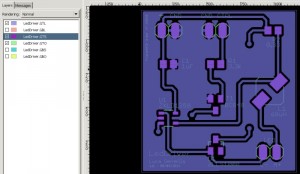

Before sending those files to SeeedStudio, I strongly suggest to check their content with a Gerber editor/viewer: in my experience sometimes I found errors in the exported files (for example if you use proportional fonts, they may change size).

A great opensource software is Gerbv, which has been ported also on Windows platforms.

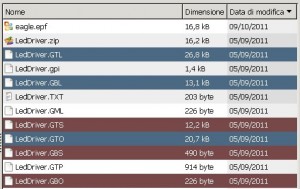

To open your project, click on File -> Open layer(s)…

Choose (pressing CTRL key, you can select more than a file at the same time) the 7 files you have to send to SeeedStudio:

- .GTL (top layer)

- .GBL (bottom layer)

- .GTS (solder stop mask top)

- .GBS (solder stop mask bottom)

- .GTO (silk top)

- .GBO (silk bottom)

- .TXT (drill sizes and positions)

Hiding/Showing each layer you can check if export was successful:

If everything looks good, prepare an archive with the files listed above.

Connect to SeeedStudio website, in the page where you can order the FusionPCB service.

Upload your ZIP file:

and complete your order choosing PCB quantity and parameters; you can follow the order status in the customer area of Seeed’s website.

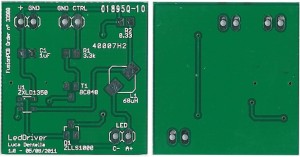

After some weeks, here are the PCBs…

Molto interessante come notizia, ci sto facendo un pensierino. E grazie per la guida all’ordine.

grazie a te per il feedback!

davvero complimenti!

appena ho qualche momento di libertà vedrò di buttare giù uno schema e proverò il servizio il prima possibile!

p.s. sono arrivato qui da dangerousprototypes con grande piacere

grazie, in effetti da quando DP ha messo il post il grafico delle visite si è impennato 😉

Dogana? Tempi?

tempi di produzione circa 6 giorni (SeeedStudio lavora a batch quindi dipende se sei “fortunato” e invii l’ordine quando stanno per mandarne uno in lavorazione); tempi di spedizione una settimana per arrivare in Italia (tracking su HKPost)… da qui l’enigma delle poste italiane: a me il pacchetto è rimasto fermo in dogana due settimane.

Per quanto riguarda le spese, se l’importo è basso (il mio ordine era da 10 euro) passa esente.

Hi, I work with Target 3001 and have a question about the data files for Seeed Studio. How should the drill file be structured? And on which layer should be the outline, and how does it work when the outline is on the silk layer ?Target 3001 all exported into individual files *.Drill, *.Outline… all other layers looks good.

regards from germany

Hi,

when i do the DRC check, i get a bunch or ‘stop mask’ errors.

i have never seen that before, it seems that the error triggers every time there is a pad and silkscreen at the same place.

Do you have any idea how i would solve that? is it a problem at all?

thanks

Hi!

You’re right, those errors mean that you have a silkscreen on the top of a pad… you can ignore it as it isn’t a problem for Seeed’s service.

I am a KiCAD user, and have not had any issues with any files sent on multiple orders. I do have the option to clip the silkscreen layers when generating Gerber files and have done this on my last two orders and stated on my email with file transmittal. Does this help reduce the pre-fabrication time needed, or do they clip back further than the solder mask?

As requested I also put the order number on the top silkscreen and then put a call-out leader pointing to the location outside of the board edge. Does the call-out help even though the call-out needs to be clipped prior to production?

I am from the school of the design for manufacture-ability and by providing files that are able to go directly into production reduces cost as the board house does not need to perform this task prior to making the screen.

It would be nice to get feed back on these two items if they help reduce pre-processes time and keep costs down.

Hi, i tried my Pcb on Gerbv 2.6.0. I used proportional text font but they look like vector font in Gerbv. So,some texts changed position. I designed my pcb in Eagle. Is it effects like this on real pcb?

Another Question: In cam processor what we choose outut device? Is it GERBER_RS274X ?

Hi peo,

proportional fonts don’t work well with gerber export, you’d better to use vector fonts.

In CAM processor, you have to choose the .cam file provided by Seeeds (Seeed_Gerber_Generater_v0r95_DrillAlign.cam)

Thanks for tutorial…. but not the PCB design example. It is switchmode device ant distance between L and swith MUST be short ant thick. And to the caps. 🙂

Hi,

Very good guide.

CAM process generates more than 7 files you say, should I ignore the rest? (using seed studio cam file)

thank you.

Hi!

Yes, FusionPCB needs only the 7 files listed in my tutorial: you can ignore the other ones.

Hi Luca

I followed your excellent tutorial and submitted my zip file to seed studio however I have just had an email saying that my design doesn’t include drill sizes. The *.TXT file was included in the zip and when I view the drill layer in Gerbv I can see a lot of circles with a forward slash through them as well as a few egg-timer type symbols. Could you tell me where I’m going wrong please?

Thanks

This tutorial is great! Thanks for doing it.

I use Eagle 6.5.0 and gerbv 2.6.1

Is it normal that the dimension lines are on all layers?

Hi Alain, yes.

Grazie per le preziose info Luca, utilissime per chi ha a che fare con seedstudio per la prima volta!

Here’s another cheap PCB service, starting from $9.9, choose the color yourself.

http://www.elecfreaks.com/store/pcb-service-c-39.html

thanks!

Hi Luca & everyone,

This is Shuyang from Seeed fusion.. Thank you for that wonderful guide. I would like to put this link on our website. What do you think?

Please feel free to contact me in shuyang@seeed.cc for any question.

Thanks!

Shuyang

Hi! Of course I’m happy if you link my tutorial on your website! Thanks